#Aquaponics could address land, water and pest issues—but will it pay off? (via @deliciousliving) #agriculture

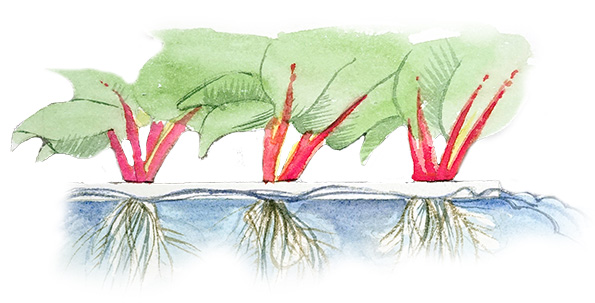

Shoe soles dripping with sanitizer, I step inside. It’s March—typically Denver’s snowiest month—yet I’m surrounded by thriving leafy greens floating on waist-high styrene rafts atop gurgling vats. The greenhouse is clean, tidy and bright, and the greens impressive—each a photo-ready example of its variety. Behind me, hundreds of tilapia and striped bass circle inside large tanks. Their job? Eat, swim, poop. Thus fertilized, the fish water flows through the hungry roots dangling in “rivers” beneath the greens and then, scrubbed clean by the plants, recirculates back to the fish.

This is aquaponics—aquaculture (raising fish) meets hydroponics (soil-free farming)—the elegance of which is seductive. Especially the semblance of symbiosis it brings to the sterile world of indoor farming. I’m visiting Flourish Farms, a 3,000-square-foot indoor farm only three miles from the heart of downtown Denver, Colorado. Cofounder Tawnya Sawyer explains how all these living elements—greens and fish—will be harvested, while describing the “perfect nutrient supply” the fish provide.

“We have the benefit of capturing nutrients that would be wasted in independent systems,” Sawyer explains. “The beauty is we don’t have to add a lot of fertilizers in the form of salts that are often either mined or expensively manufactured at very high costs to natural resources, pollution and waste.”

Also compelling are the significant increases in yield (Flourish harvests about half, per square-foot, of traditional lettuce farmers—but does so every two weeks) alongside substantial reductions in pests, climate susceptibility, food waste, food miles and food deserts. That’s in addition to what is likely the most profound savings, especially given the recent years-long California drought: “We use about 10 percent of the water of traditional agriculture,” Sawyer says. “Although this is 11,000 gallons of total water circulating, we’re not losing it to the ground, we’re not wasting it, it’s not evaporating.”

Supply: Hooked on ’ponics

A dozen miles northwest of Denver, breaking ground later this year, Altius Farms, a 15,000-square-foot indoor “tower farm” will grow specialty greens, microgreens and culinary herbs. The towers are 8-foot-tall “aeroponic” structures, in which plant roots are merely misted with nutrified water. Another 500 miles northwest, three-story Vertical Harvest is opening its doors in Jackson, Wyoming, using hydroponic trays moving on a mechanized carousel to optimize light from the south window and grow greens and tomatoes for local distribution.

A dozen miles northwest of Denver, breaking ground later this year, Altius Farms, a 15,000-square-foot indoor “tower farm” will grow specialty greens, microgreens and culinary herbs. The towers are 8-foot-tall “aeroponic” structures, in which plant roots are merely misted with nutrified water. Another 500 miles northwest, three-story Vertical Harvest is opening its doors in Jackson, Wyoming, using hydroponic trays moving on a mechanized carousel to optimize light from the south window and grow greens and tomatoes for local distribution.

Each of these farms claims high outputs with low inputs. Many are eager to tackle social problems, too. Flourish, for instance, sells exclusively within a five-mile radius—and sells on a sliding scale to local residents, addressing a Denver food desert. Vertical employs the developmentally disabled throughout their operation. So, why aren’t we seeing more of this?

“One of the things I think is not told when it comes to urban agriculture is how hard it is,” says Altius cofounder and CEO Sally Herbert, who lists complications with zoning, water rights, debt and equity. “What we’re learning here is that traditional lending institutions don’t get this yet,” she says. “I think we have to shift that thinking if we’re going to grow our food locally: How do we foster this small-farm resurgence?”

Then there’s business expertise. A global executive with 25 years of team building, operations and supply chain experience, Herbert’s got it, but not everyone getting into farming does. Herbert broke down some of the economics for me. The investment of creating a climate-controlled environment, she says, is nearly $100 per square foot. Land cost and ownership is another big variable. Once up and running, though, she says 4,000 square feet can grow an acre’s equivalent of, say, kale with 14 growing cycles per year. “The margins far exceed what you see with traditional farming,” she adds. “We’ll be cash-flow positive in month six.”

Maybe so, but the revenues Sawyer expressed were well under $100,000 annually, and that’s not counting farm inputs (such as fish food) or salaries. To go big, it seems, aquaponics has to join the ranks of other infrastructural programs (think energy, transportation—even traditional agriculture) calling on subsidies to get them started and keep them going.

Indeed, Vertical received a grant for $1.5 million from the Wyoming Business Council. “We couldn’t have done this project without that,” admits cofounder Nona Yehia. The company was also granted a small swath of city-owned land. At only 30 feet by 150 feet, however, Vertical had a difficult decision to make. “We could put up a hoop house and call it a day,” says Yehia, “or we could make this something that could work 365 days a year, producing as much food as possible and as many jobs as possible. That’s really where the idea to go vertical came from.” That, too, is where exorbitant costs roll in: a high-tech indoor farm is millions of dollars in the making.

Demand: The organic conundrum

“Local produce is a premium compared to the mass-produced stuff,” says Herbert. “You’re getting non-GMO, pesticide free,” she says, describing Altius’ roots-on, living-plant distribution model. “When you serve that, it was living three minutes ago. The nutritional content and flavor are beyond anything you can get that’s been sitting in a refrigerated truck for 1,500 miles.”

The controlled environment reduces or eliminates the need for pesticides, too. Yet, these growing methods don’t qualify for organic certification, whose regulatory standards are rooted in soil. Fish don’t qualify either. So, while growing at a premium, they are doing so without the organic opportunity for premium pricing.

Herbert is unfazed. “Does organic matter to the consumer anymore?” she asks. “Local trumps organic any day, everywhere I go.” She’s also dubious about the soil distinction. “Plants drink their food; they don’t eat it,” she says, and that is why hydroponics work. A debate, then, centers around whether organics can welcome mined mineral salts. They’re the same compounds all plants use to grow, Herbert argues. “Are they coming naturally from the earth? Yes, of course they are.”

Soil is dirty, and consumer approval is complicated. Although we don’t want dirt at the dinner table, we’re reluctant to see it go from our farms. Maybe that’s why these farmers are relying heavily on chef partnerships for distribution, where the high quality shows up on the plate, but the high-tech remains one degree removed from the consumer’s purchase process. This may be another nature versus global-crisis-solving-technology debate. And the organic marketgoer is approaching with intrigue and hesitation.